1. Advantages Over Traditional Coverings

Demolition film presents several distinct advantages over traditional coverings such as tarps or blankets, making it a preferred choice in modern construction and renovation projects.

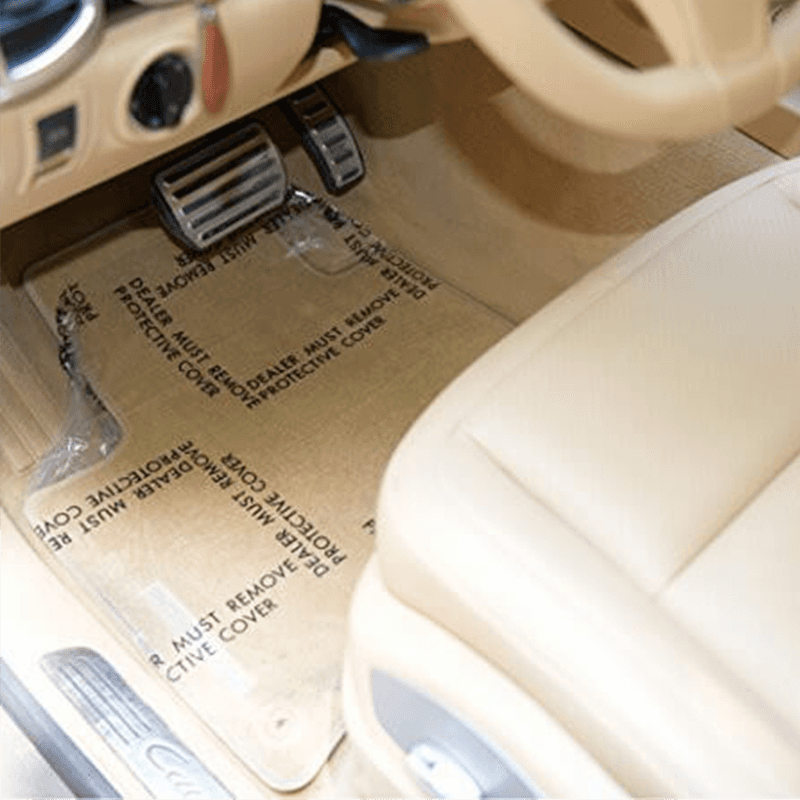

a)Precision Fit and Surface Conformity: Demolition film is manufactured in varying thicknesses and widths, allowing for precise customization to fit different surfaces and project needs. This tailored fit ensures complete coverage without excess material, minimizing the risk of debris or dust seeping underneath, which is a common issue with loose-fitting tarps.

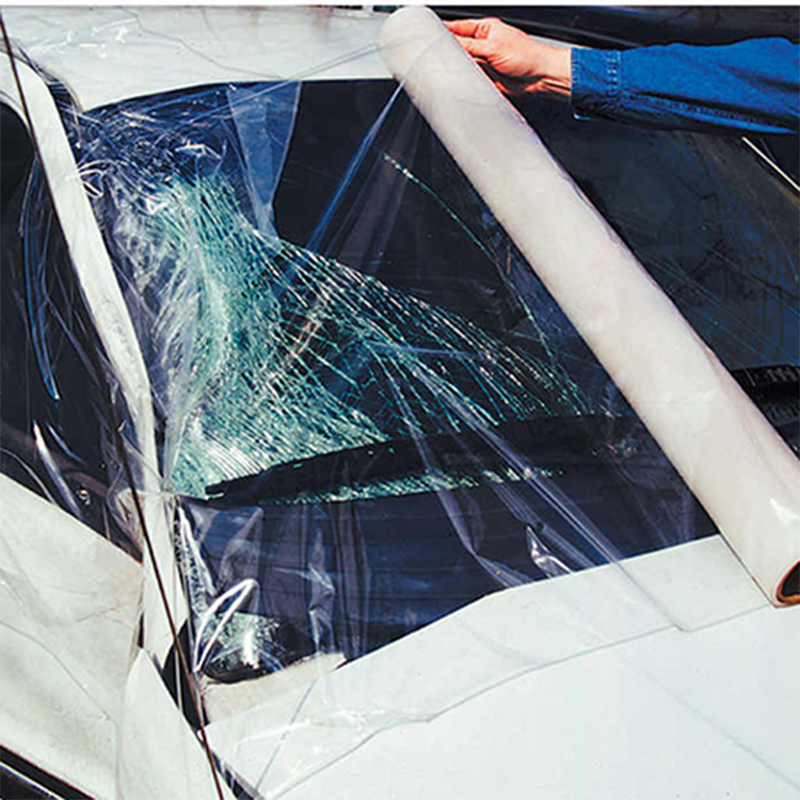

b)Enhanced Protection and Durability: Unlike traditional materials that may tear or degrade quickly under harsh conditions, demolition film is engineered from high-quality polyethylene or polypropylene. These materials offer superior tear resistance, durability, and weather resistance, ensuring prolonged protection against impacts, abrasions, and weather elements throughout the demolition process.

c)Static Cling Properties: Many demolition films are designed with static cling properties, enabling them to adhere tightly to surfaces without the need for adhesives. This feature not only simplifies installation and removal but also prevents the film from shifting or lifting during construction activities, maintaining continuous protection.

d)Easy Application and Removal: Compared to cumbersome tarps that require securing with ropes or ties, demolition film is lightweight and easier to handle. Adhesive-backed variants simplify application by securely adhering to surfaces, even on irregular or vertical surfaces such as walls or windows. Removal is equally straightforward, often requiring minimal effort and leaving behind no residue or damage to the protected surfaces.

e)Protection Against Contamination and Hazardous Materials: In demolition projects involving hazardous materials like asbestos or lead-based paints, containment is critical for safety and regulatory compliance. Demolition film provides an effective barrier, encapsulating contaminants and preventing their spread, thus safeguarding workers and the environment from potential health risks.

2. Best Practices for Application

Proper application of demolition film is crucial to maximize its effectiveness in protecting surfaces during construction and renovation activities. Implementing these best practices ensures optimal performance and minimizes the risk of damage or inefficiencies.

a)Surface Preparation: Before applying demolition film, ensure that the surface is clean, dry, and free of debris. Remove any existing adhesive residues or contaminants that could compromise the film's adhesion. Smooth out uneven surfaces to facilitate better contact and adherence of the film.

b)Temperature Considerations: Temperature can significantly affect the performance of demolition film. For adhesive-backed films, ensure that the ambient temperature and surface temperature are within the manufacturer's recommended range during application. Extreme temperatures can affect adhesive strength and film flexibility, potentially leading to installation difficulties or reduced effectiveness.

c)Proper Application Techniques: Apply the demolition film carefully and systematically to ensure complete coverage of the targeted surface. Begin by aligning one edge of the film with the starting point and gradually unroll or unfold it across the surface. Use a plastic squeegee or roller to smooth out any air bubbles or wrinkles, ensuring firm adhesion and uniform contact with the surface.

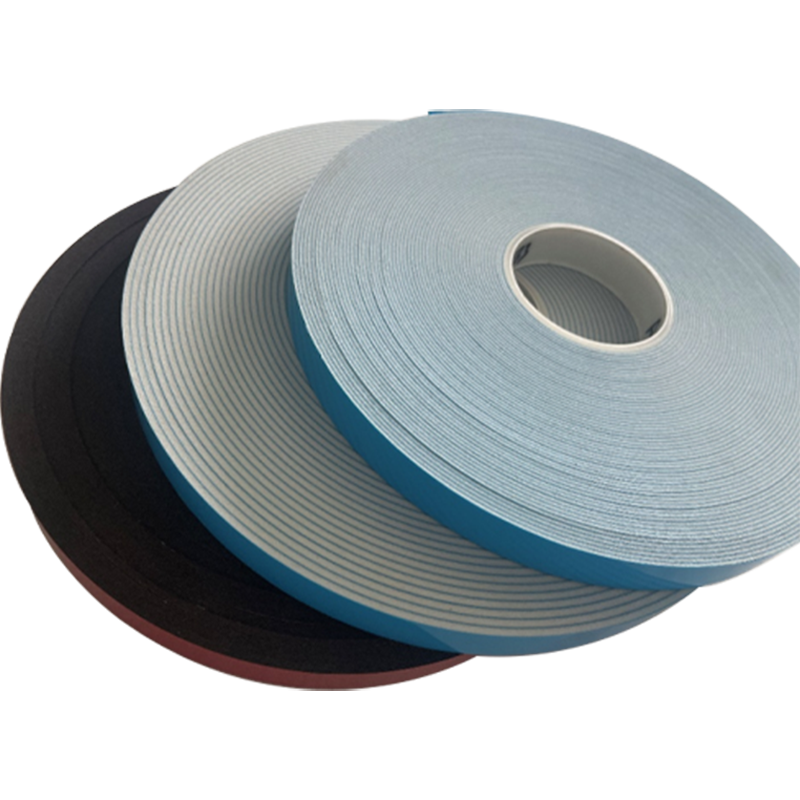

d)Overlap and Sealing: When covering large areas or joining multiple sheets of film, overlap adjacent sections by several inches to create a seamless barrier against dust and debris ingress. Ensure that overlaps are securely sealed to prevent gaps or openings that could compromise the protective enclosure. Use specialized tape or adhesive strips designed for use with demolition film to achieve secure seals.

e)Removal Techniques: Plan for the efficient removal of demolition film once construction or renovation activities are complete. Follow manufacturer guidelines for safe removal to minimize potential surface damage or residue. Consider using tools such as utility knives or heat guns for adhesive-backed films to facilitate easier removal without leaving adhesive residues behind.

English

English

English

English русский

русский Français

Français Español

Español Português

Português عربى

عربى